product center

- ● Beer brewing equipment system

- --brewpub equipment

- --Industry brewery equipment

- --Micro-brewery equipment

- ● Beer filling system

- --Beer canning machine

- --Beer glass bottling machine

- --Beer kegging machine

- --PET Bottling machine

- ● Brewery corollary equipment

- ● Single tank

- --Bright Beer tank

- --CIP Unit

- --Fermentation tank

Introduction

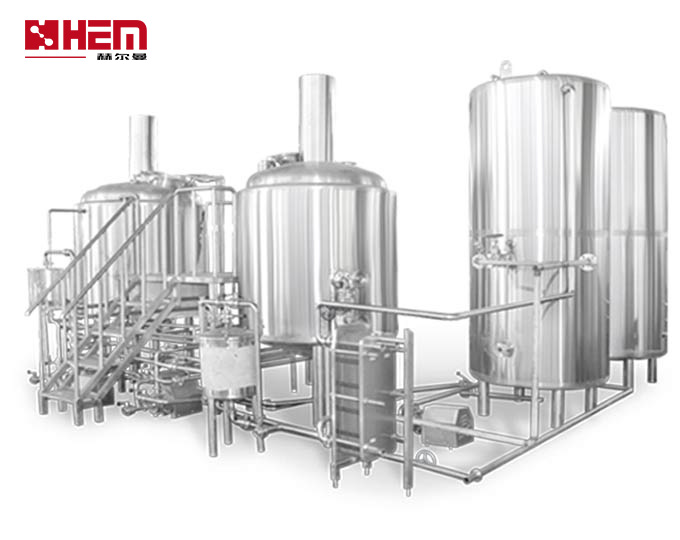

A commercial brewery is focus on regional market. The capacity request is not so high than macro breweries. Their beers are always sold on shelf in bottle or canning. We are involved in providing different types of medium scale industrial breweries to clients worldwide. The output is mainly 15kL, 20kL, 30kL, 50kL per working day. The complete setup of these breweries is in compliance with modern brewery standards and specifications. These products enable systematic execution of milling, mashing, fermentation, filtration, filling and other related processes. We subject each brewing system to stringent testing procedures before launching them in the market.

Specification

| Output/Brew | 15kL |

| Brews/Day | 2~4 |

| Output/Month | 300~ 600kL |

| Electric Supply | 3phase/380(220, 415,440)v/50 (60)Hz |

| Heating Source | Steam/Directly Fired |

| Area Request | >700M2 |

| Brewmaster | 5 |

Configuration

1.Malt Milling Unit

Particle adjustable rolling crusher for dry or wet milling

Flexible or steel auger or a bucket type conveyor to directly lift the milled grain to mash tun

2.15KL Brewhouse Unit

Mash tun, Lauter tun, Boiling Kettle, Whirlpool tun in various combination

Hot water tank and cold water tank for optional in special combinations

Infusion or decoction brewing methods are designed exactly

Stainless steel cladding is even the unique because of easy maintenance and clean

Two stages or single stage heat exchanger for wort cooling

Completely stainless steel integrated work platform

Sanitary and efficiency wort pump

All pipings, pipes maniford and fittings

3.15KL or 30KL Fermentation Unit

Standard stainless steel conical cylindrical fermentation tanks

Single, double, triple or more size as brewhouse is common used in commercial breweries

Tanks quantity is exactly calculated by fermentation cycle for various beers

Roof walkway is for special request

All manhole, valves, pressure gauges, fittings etc are included

4.Beer Filter Unit

Large plate-Frame or Candle type DE (diatomite earth) filter is used for clarify the beer

5.15KL or 30KL Bright Beer Tank Unit

Standard stainless steel bright tanks for beer maturation, conditioning, service, carbonation

Single,double size or more as fermenter is common used

Tanks quantity is exactly calculated for various beers and the function

All manhole, valves, stone, gauges, fittings etc are included

6.Cooling Unit

Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing

Efficiency chillers or refrigerators with fryon to supply cooling energy

Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

All pipes, fitting, insulation materials are included

7.Controlling Unit

Electrical controlling cabinet with temperature, on-off controlling for brewhouse

Electrical controlling cabinet with temperature, on-off controlling for cooling parts

Temperature controller, thermocouple, solenoid valves etc are included

PLC with touch screen panel for special request

8.Beer Dispense

Semiauto or automatic bottling machine with rinsing, filling, capping, labeling etc

Semiauto or automatic canning machine

Flash pasteurizer or tunnel pasteurizer is available

9.Other Facilities

Portable CIP system for cleaning the tanks

Steam boiler for brewhouse heating

Water treatment for brew water

Oil free air compressor

Brewery lab instruments for beer quality test

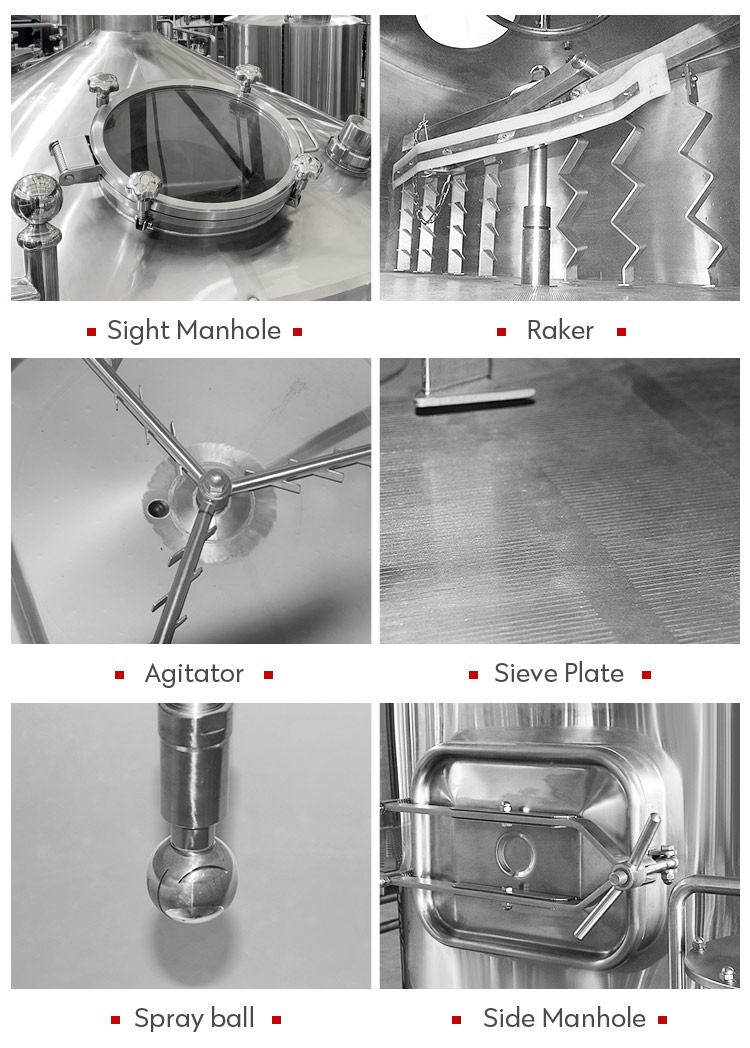

Configuration details

After-Sale Service

We guarantee the quality of the electrical elements within 1 year and tanks body within 3 years. If the electrical elements go wrong without artificial factors within one year, we will freely provide them or maintain them for you.

After warranty, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support.

We can also dispatch our engineer to your brewery to install and adjust the machines for you. He can also train your staff to use the equipment.

FAQ.

How about the installation?

We can supply the installation. There are two options. The first option: We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side. The second option: On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, the buyer afford the transportation cost.

008653188825980

008653188825980