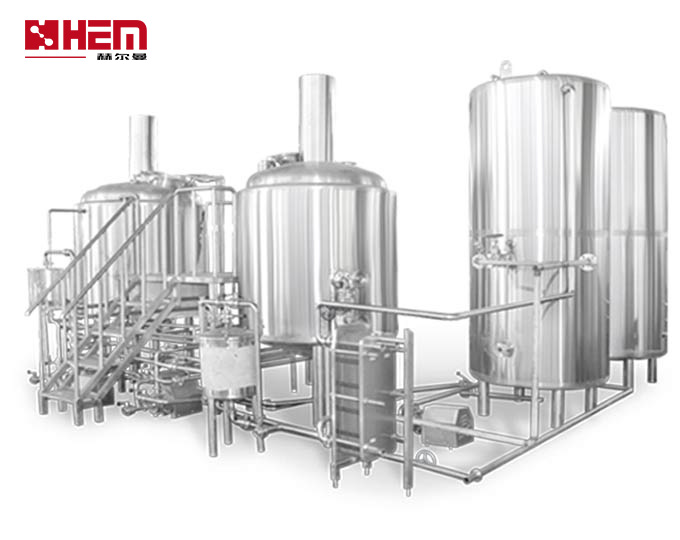

product center

- ● Beer brewing equipment system

- --brewpub equipment

- --Industry brewery equipment

- --Micro-brewery equipment

- ● Beer filling system

- --Beer canning machine

- --Beer glass bottling machine

- --Beer kegging machine

- --PET Bottling machine

- ● Brewery corollary equipment

- ● Single tank

- --Bright Beer tank

- --CIP Unit

- --Fermentation tank

PET bottle filling machine: PET bottle rinsing/filling/capping 3-in-1 Unit is a kind of professional filling machine integrator for non carbonated water and non carbonated water, such as cola, etc. It is multifunctional which can be used for rinsing, filling and capping.

HG-BGZ rinsing/filling/capping 3-in-1 machine is suitable for glass bottle carbonated water filling line. The machine adopts bottle neck clip conveyor manner, only to change a small parts that bottle apply to different kinds of bottle size, and min. the abrasion of the bottle body, smooth conveyor. The filling manner is advanced isobar filling, accurate control of filling liquid level, and avoid the generation of bubble during filling. Sanitary cycle pipeline makes sure of the quality of the products. The equipment equipped with automatic oil-dry lubricate device, and oiling lubricating points when needs, and extend the life time of the equipment.

a. Rinsing part:

The machine is rotary rinsing machine, mainly used for glass bottle. The new bottle enters into the equipment through bottle distribution screw and star wheel, and its neck is clipped to mouth down by the clamp and turner device, first step, rinsing with disinfector and second step rinsing with sterilized water, dry after rinsing, and turn to mouth up automatically, then enters into the filling machine through bottle-outlet star wheel conveyor. The main structure of the equipment, contact parts with rinsing medium and external protective cover are stainless steel material; opening gear drive.

Rinsing machine inlet pipe is equipped with pressure gauge, to make sure of rinsing pressure;

Rinsing machine is equipped with water collector to recycle rinsing water and save energy;

When rinsing, the consumption of water rinsing for each type of bottles are:

0.5/0.6L>190ml

1.25/1.5L>350ml;

The machine will stop rinsing automatically when no bottle or shut down; and start to rinsing when bottle inlet.

b. Filling part:

The filling machine adopt short pipe filling valve, to control content of oxygen in the bottle making use

of gas displacement manner; the valve is equipped outside of the cylinder, to avoid liquid level undulate, mirror polish for inner part of the cylinder, to make sure no dead angle for cleaning;

●External mechanical valve, no disturb for the product in the cylinder when running, and makes sure the stability of filling.

●No spring built-in, to reduce a good many unstable factors in the filling.

●Chronological forced open the air valve, liquid valve, moves smoothly and can truly achieve isopiestic pressure to open valve, to avoid the rolling product.

●Modulization design, for easy disassembly and maintenance

c. Capping part:

Capping machine rotates with rotate plate through reducing box, to make the cap leave hopper from cap exit with the function of centrifugal force. There are both positive and negative cap at the exit of separation devices, when anti-cap passes, the cap automatically fall into the return pipe, and blown to hopper automatically through the wind. Only right cap can be successfully enter into the slide, the quantity of caps in the hopper will be automatically inspected by the photoelectric switch to control the machine, to achieve the best results for cap chute.

After-Sale Service

1 year warranty for the machine. If the electrical elements go wrong without artificial factors within one year, we will freely provide them or maintain them for you.

After warranty, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support.

We can also dispatch our engineer to your brewery to install and adjust the machines for you. He can also train your staff to use the equipment.

FAQ.

How about the installation?

We can supply the installation. There are two options. The first option: We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side. The second option: On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, the buyer afford the transportation cost.

008653188825980

008653188825980