product center

- ● Beer brewing equipment system

- --brewpub equipment

- --Industry brewery equipment

- --Micro-brewery equipment

- ● Beer filling system

- --Beer canning machine

- --Beer glass bottling machine

- --Beer kegging machine

- --PET Bottling machine

- ● Brewery corollary equipment

- ● Single tank

- --Bright Beer tank

- --CIP Unit

- --Fermentation tank

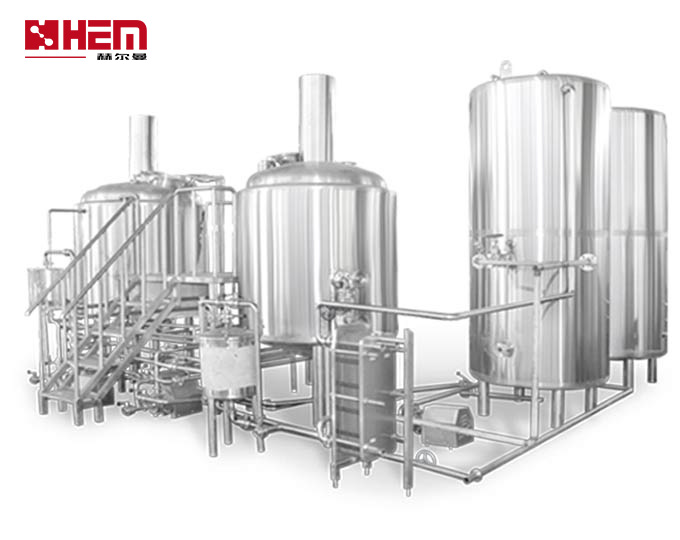

Description

Beer distribution tanks are often also called serving tanks, tax determination tanks or clear beer tanks (=CBTs), Vertical Bright Beer Tanks (=BBTs) or maturation or conditioning tanks. These tanks are used for the storage of the beer prior to being served or packaged. Depending on their application the beer serving tanks can be glycol jacketed or can be located in a cold room.For brewpubs serving is often done by pumping or pressurizing the beer toward the serving location.

Standard Configuration

Function:Beer maturation/conditioning/serving/filtered beer receiving

Tank Capacity: 8 bbl (+20% Headspace minimum)

Dimension: Φ1260mmx2100mm

Interior Shell: SUS304 full welded; TH=3mm

Exterior Shell:SUS304 full welded; TH=2mm

100% TIG welding with pure argon gas shield

Interior Finish: Overall polishing to 0.4~0.6 μm without dead corner

Insulation: Polyurethane; TH=80mm

Glycol Jacket: Dimple plate on side wall

Stringent tank leakage test by water and pressured gas

Stringent Jacket leakage test by water and pressured gas

Dished head and bottom

Sanitary top mounted manway

CIP arm with 360° coverage CIP spraying ball

Full sanitary sampling valve

Mechanical relief valve 2 bar on CIP arm

Carbonation port with stone

Shockproof pressure gauge on CIP arm

Tri clamp discharge arm with butterfly valve

Thermowell for high accuracy temperature sensor

3pcs completely SUS304 heavy duty legs with leveling pad

Sanitary level tube with stainless steel ball valves

Complete valves, fittings and all parts

After-Sale Service

1 year warranty for the machine. If the electrical elements go wrong without artificial factors within one year, we will freely provide them or maintain them for you.

After warranty, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support.

We can also dispatch our engineer to your brewery to install and adjust the machines for you. He can also train your staff to use the equipment.

FAQ.

How about the installation?

We can supply the installation. There are two options. The first option: We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side. The second option: On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, the buyer afford the transportation cost.

008653188825980

008653188825980